METAL TAPPING AND DISCHARGE

Storvik is a specialist in metal and bath tapping, we supply a wide range of products with the aim to improve the tapping and maintenance operation. In more than 30 years Storvik has provided the industry with crucibles, lids, tapping consumables and solutions.

With use of our proprietary grey iron alloy PjN-G we reduce the total cost of ownership for the customers. Latest development is us of grey iron lids which eliminates the need of refractory lining and increases the lifetime performance with proven 60%.

Storvik can design and certify crucibles and lids according to pressure directive.

Product portfolio:

- Metal and bath tapping lid

- Crucibles for bath and metal

- Cast iron lining for bath crucibles

- Tapping consumables

- Crucible cleaning machines

- Equipment for cleaning of tapping pipes

- Unique solution for metal filling in furnace

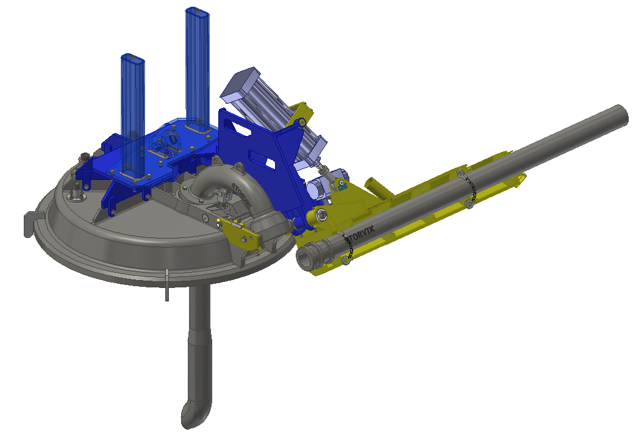

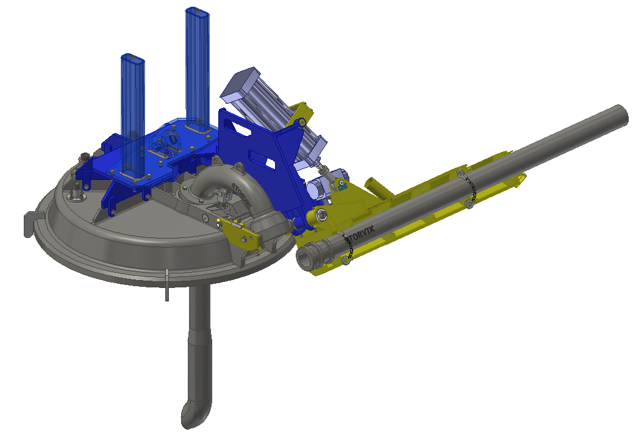

TAPPING AND DISCHARGE TUBE CLEANING

The multi-functional machine for drilling and cleaning of tapping and discharge pipes is operated with remote control from the vehicle or in separate cabin placed close to the machine. The machine is hydraulically operated and can handle hot tapping pipes in full length up, while the tapping pipe is assembled onto the vehicle.

It also handles cleaning of the discharge pipe in a separate station, functionality is remote controlled from the vehicle. The equipment is installed in Hydro Aluminium Karmøy and Hydro Aluminium Sunndal.

- Increased HSE

- Hot and cold cleaning of tubes

- Cleaning of full-length tubes

- Operated from vehicle or remote control

- Total cleaning time 3-5 minutes

- Multi-functional for tapping and discharge tubes

- Extended tube lifetime

PNEUMATIC TUBE CLEANING MACHINE

The pneumatic tube cleaning machine (Storvik PTCM) is delivered with separate compressor to achieve good air pressure and secure best performance of the machine and optimal cleaning of tubes.

The PTCM is remotely controlled by operator and clean several tube lengths. The machine can be placed in an area close to the potroom to achieve optimal logistic for the metal transport.

We also supply the unit as plug and play with minimal requirements for installation costs.

Benefits :

- Cleaning of full-length tubes with radius

- Cleaning of hot and cold tubes

- Remotely controlled

- Cleaning time 3-6 minutes

- Metal and bath tapping tubes

- Low operational costs

- Low installation costs

CRUCIBLE CLEANING MACHINE

Storvik delivers several automatic and manual systems for cleaning of hot and cold metal and bath crucibles. Storvik has standard solutions and customized equipment. Our equipment is installed in several locations worldwide. A feasibility study with focus on functionality, degree of automatization, operational– and capital costs is advised before selecting the correct equipment for cleaning of crucibles.

- Hot cleaning

- Gentle towards refractory lining

- Semi-automatic operation

- Controlled from vehicle

- Cleaning sequence typical 12-15 minutes

- Adaptable to crane, forklift or special vehicle

- Emptying rest metal in separate bin

- Full profile drilling

- Integrated maintenance platform