About Rodding

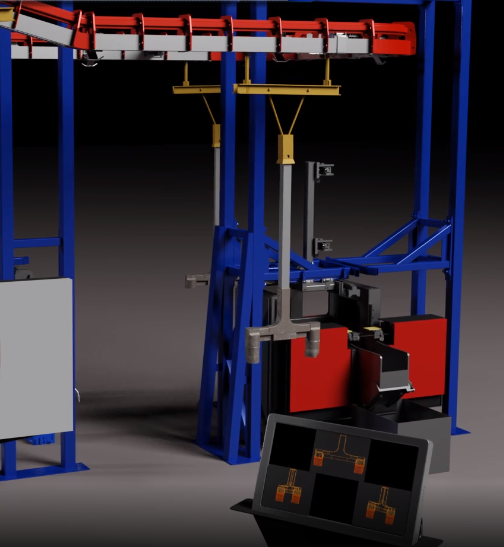

Thanks to 60 years of experiences combined with process knowledge Storvik offers today equipment, machinery, and maintenance services in Anode rodding shops.

Storvik solutions meets all customers’ requirements in terms of production capacity, layout, operations, accessibility, and demands for ease of maintenance.

Storvik has delivered studies and projects for anode rodding shop. Our main customer has been Hydro Aluminium Sunndal and been involved in studies and projects as well as turnkey deliveries to improve the stability and productivity. All these projects have been performed in close cooperation with the customer on site.

Storvik has delivered equipment such as:

- Bath Removal Mill

- Bath removal Pusher

- Anode stub cleaner

- Automatic stacking of anodes

- Bath crusher overhead conveyor

- Roller and belt conveyors

- Dust removal systems

- Handling equipment like tools and grabs

All equipment mentioned above is fully automatic controlled.

Recent deliveries include the fully automatic Inline Rod Repair. Surveillance of Anode hanger rods (stubs) are analysed by a diagnostic vision system, and anode hangers with rejected rods are automatically transferred for cutting and robotized welding of new rods prior to rodding (new cycle in electrolysis).