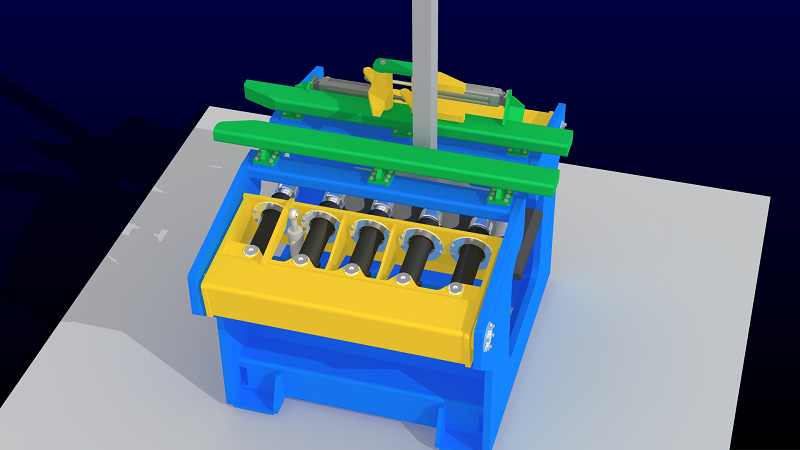

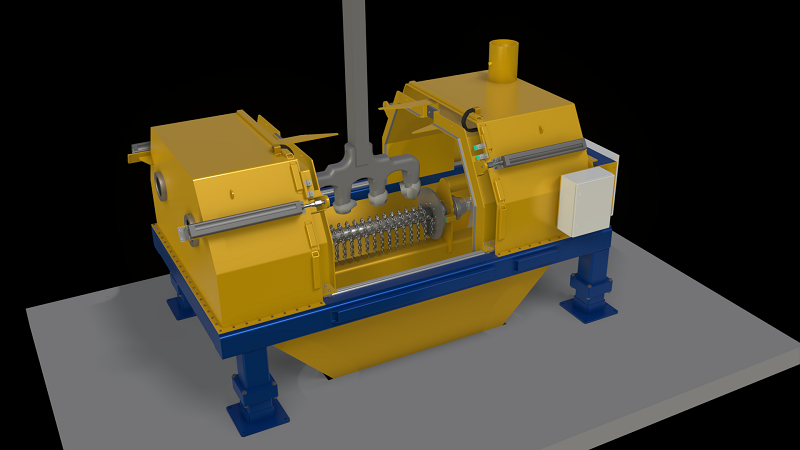

ANODE STUB CLEANER

Storvik Anode stub cleaner performs cleaning of anode stubs and yoke in the anode service shop prior to rodding or eventually repair of stubs. Specially the stubs are heavily contaminated by fouling of electrolytic bath.

The stubs need thorough cleaning prior to welding of stubs as well as rodding for a new cycle in electrolysis. Fouling of bath influence on welding process in eventual repair and reduces electric conductivity. This results in voltage drop and reduced productions in the electrolysis.

Compared with sandblasting the dust and noise impact will be reduced and contributes to an improved HSE.

The Storvik Anode stub cleaner is a favourable alternative to sandblasting due to reduced operational and investment costs, i.e. reduced OPEX– and CAPEX.

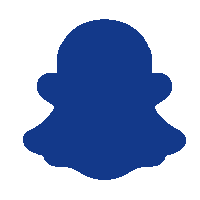

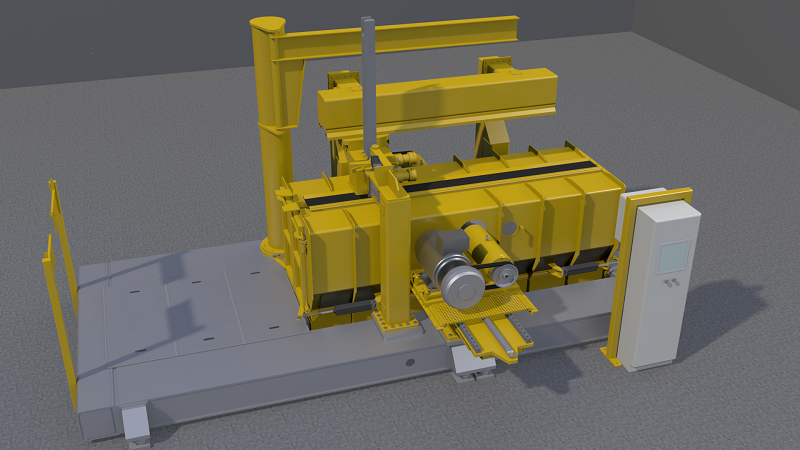

BATH REMOVAL MILL

The Storvik Bath removal Mill removes the fouling of electrolytic bath sticking to the top of the butts (remains of anode not utilised in electrolysis). The removal of bath by milling is a continuous process and performed while the butts is passing through the machine. The anode hanger and butts is attached to overhead conveyor.

By doing this prior to final removal of the butts results in a cleaner carbon fraction which normally will be recycled.

See chapter regarding Bath Removal Pusher for further improvement of this operations by another Storvik delivery.

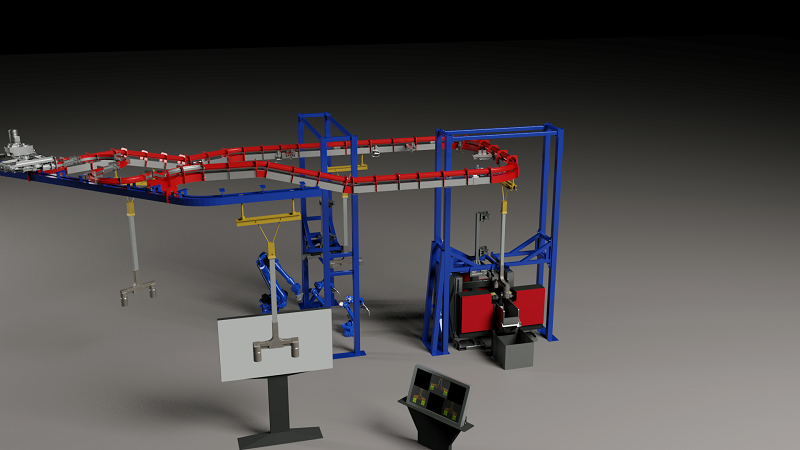

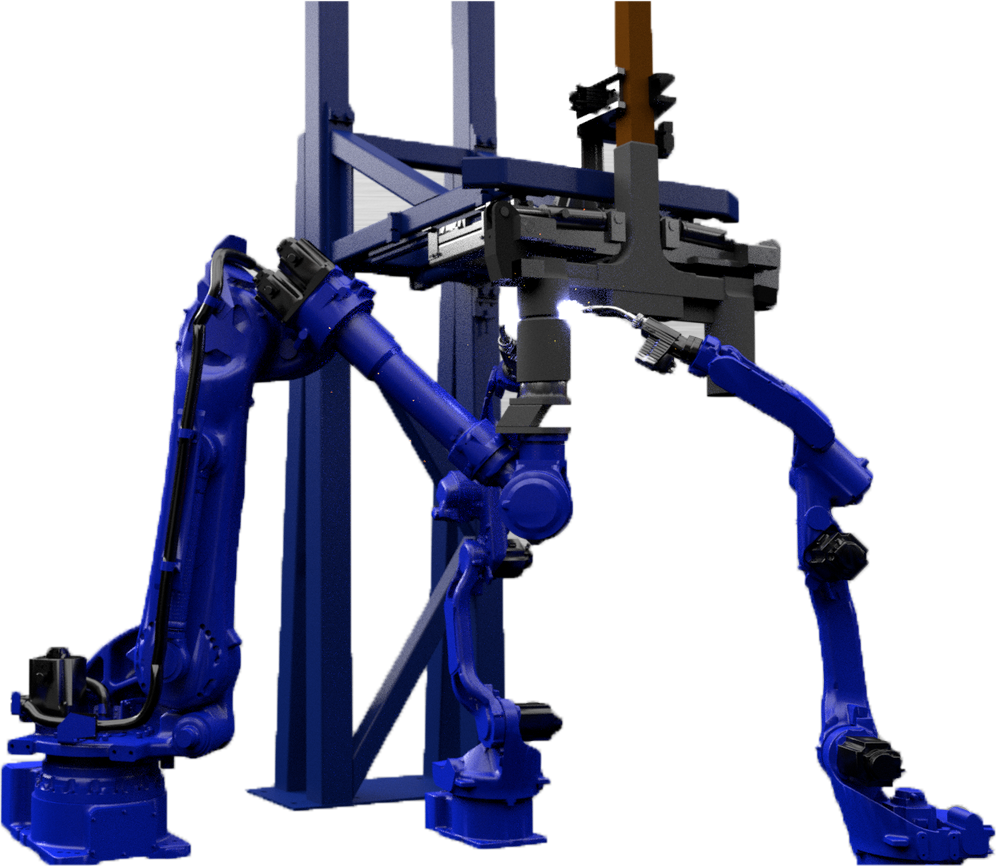

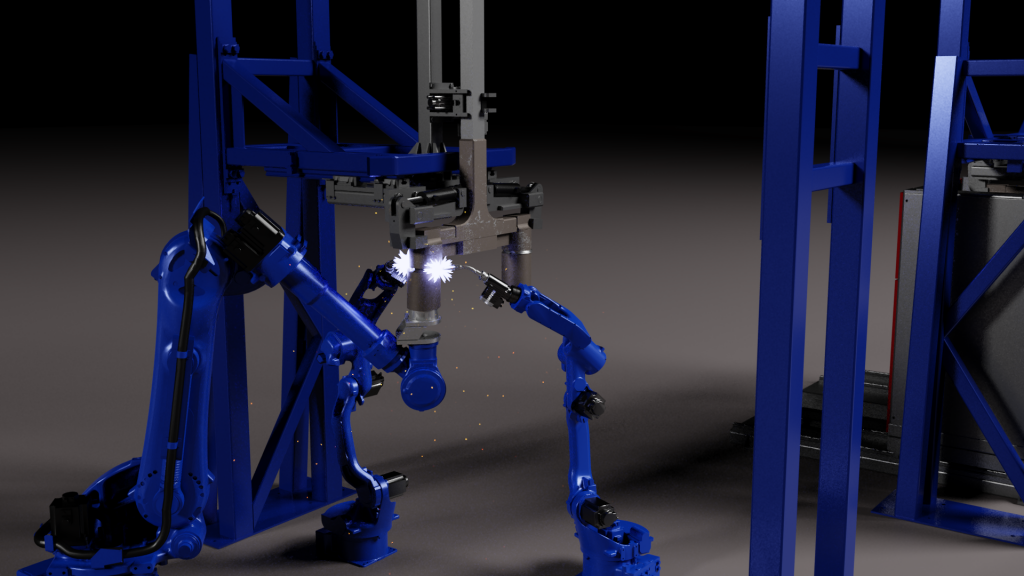

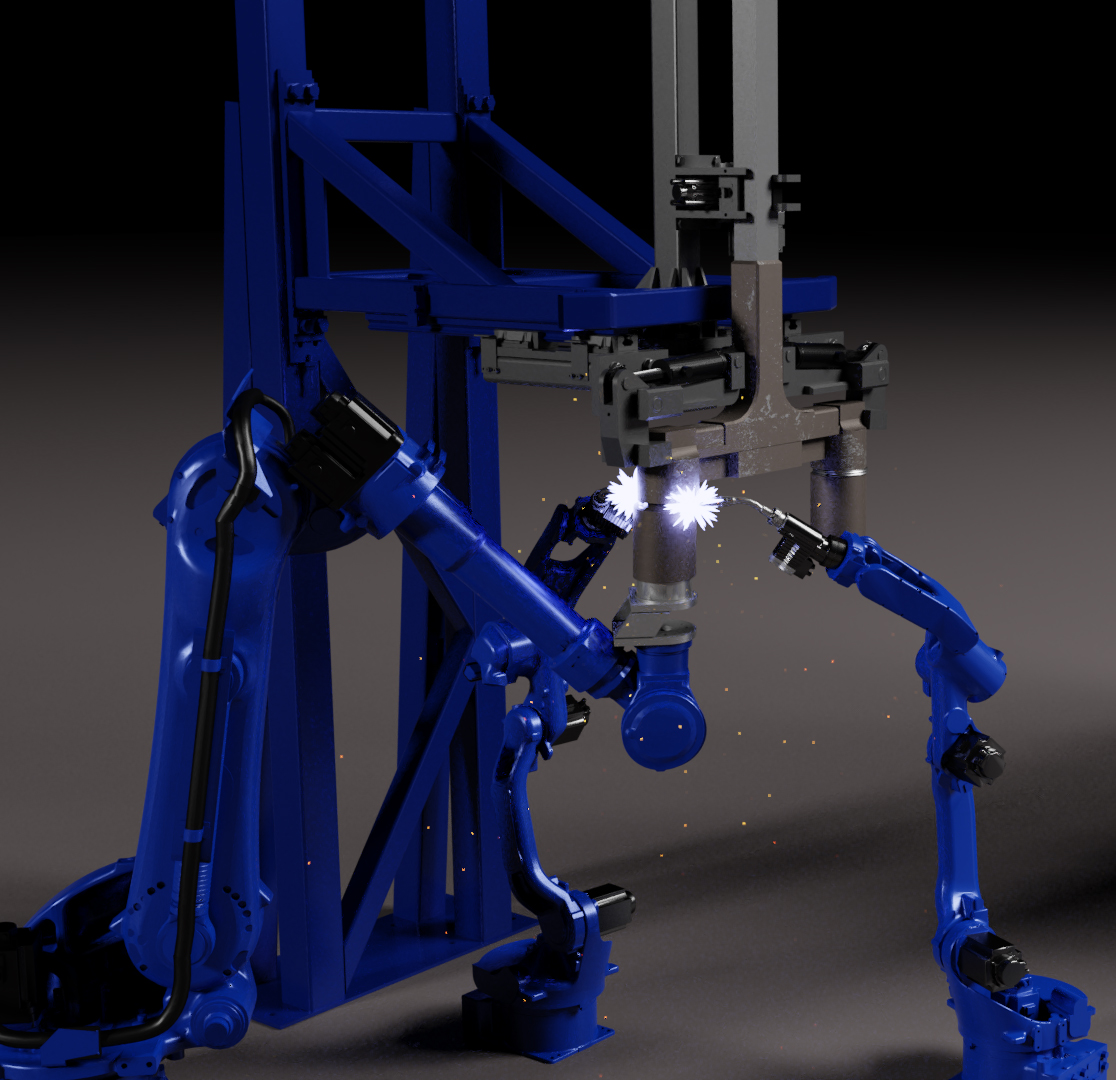

INLINE ROD REPAIR

The Storvik Inline Rod Repair line performs repair of anode Rod (stubs) automatically in anode service shop. As indicated the setup is arranged in line with the main overhead conveyor system and performs complete unmanned repair.

It starts with a Vision system observing quality of each single rod (stub) following some predetermined criteria and decide the need for repair. This is done prior to a new cycle and all anode hangers inside the acceptance criteria will continue along the main conveyor line.

The repair is done in an integrated local loop starting with cutting (bandsaw) of the rejected rod and following repair by welding. One robot picks up and arrange in position a new rod while two welding robots preforms the welding operation.

After repair, the anode hangers are returned to the main overhead conveyor for rodding.

Quality of repair is high and reliable. Furthermore, we have recognised a big achievement is reduction of labour-intensive operations and manual handling. The HSE is significantly improved, and the quantity of anode hangers out of service is reduced drastically.

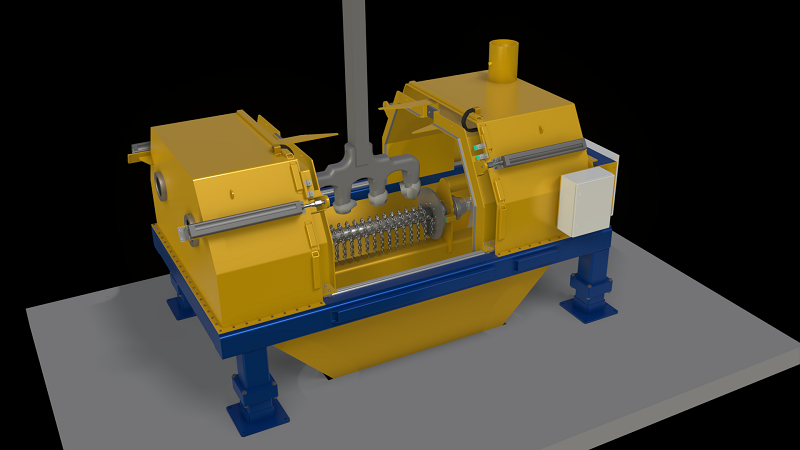

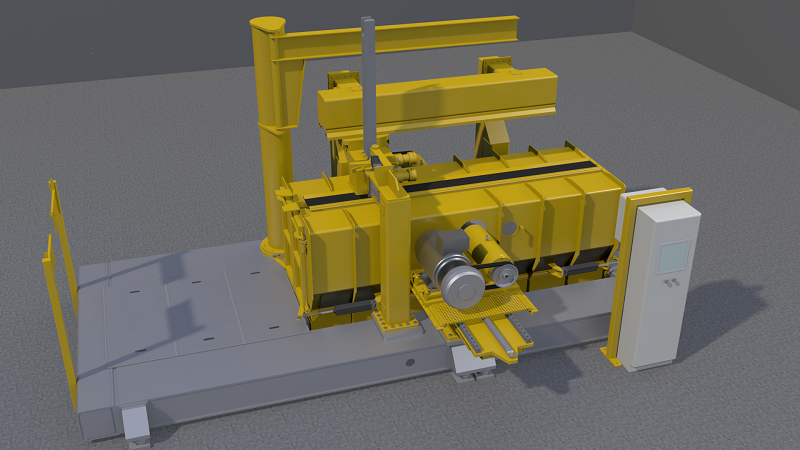

BATH REMOVAL PUSHER

The Storvik Bath Removal Pusher removes fouling of electrolytic bath from top of the butts (remains of anode not fully utilised in electrolysis) which the longitudinal milling process could not reach.

The Bath removal Pusher performs a transversal operation as the Bath Removal Mill do it longitudinal.

The Bath removal Pusher removes the electrolytic bath by hydraulic operated devices while the anode hanger with butts is passing through the machine. This is performed when the anode hanger is stopped in a fixed position for a short time.

Those two machines together remove bath from the whole top of the butts which results in a cleaner carbon fraction for recycling.

For Bath Removal Mill see other description.