Inline rod repair

Storvik AS has served the aluminium industry from the onset in Norway, and has contributed to the development of this industry for more than 60 years. Based on our experience, expertise and multidisciplinary approach we are today proud of presenting the ILRR (In Line Rod Repair).

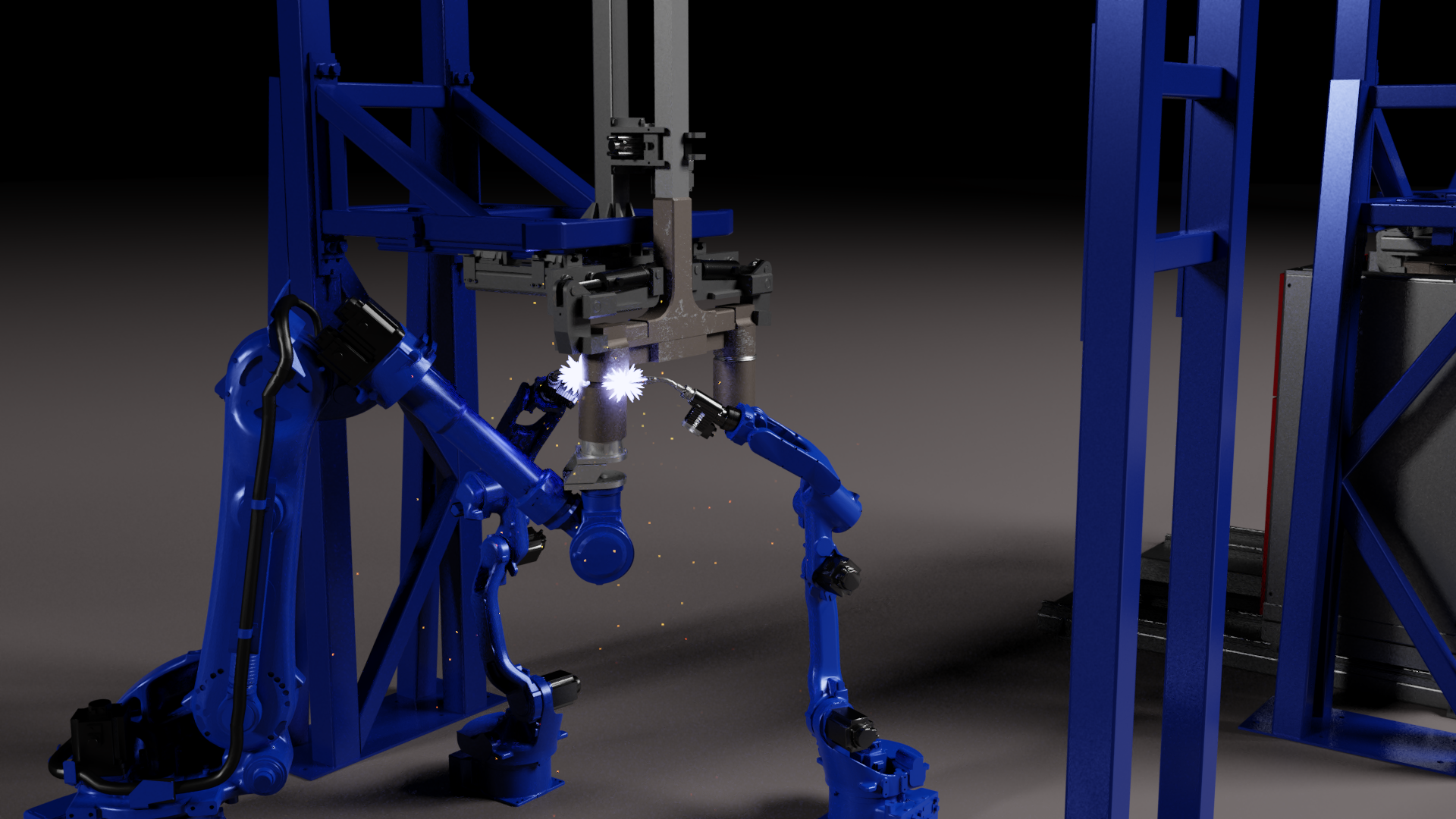

Storvik has in close cooperation with selected partners customised the robot concept for inline identification (Vision), cutting and welding of anode yokes (studs). The new anode conveyor line is an integrated solution in the rodding shop (factory).

Yokes (studs) which need to be repaired are identified and guided in to the new ILRR, while anode hangers inside the acceptance criteria will continue along the main conveyor line. As the quality of repair is high and reliable, we recognise the biggest achievement is reduced manual work and down-time, and improved HSE.

By utilisation of the ILRR we have reduced a numerous of handling and man-hours involved. Hardware components in the concept is support conveyer, Vision system, band saw, welding machines, welding- and handling robots, and a lathe machine (offline) for preparing of welding groove.