About Electrolysis

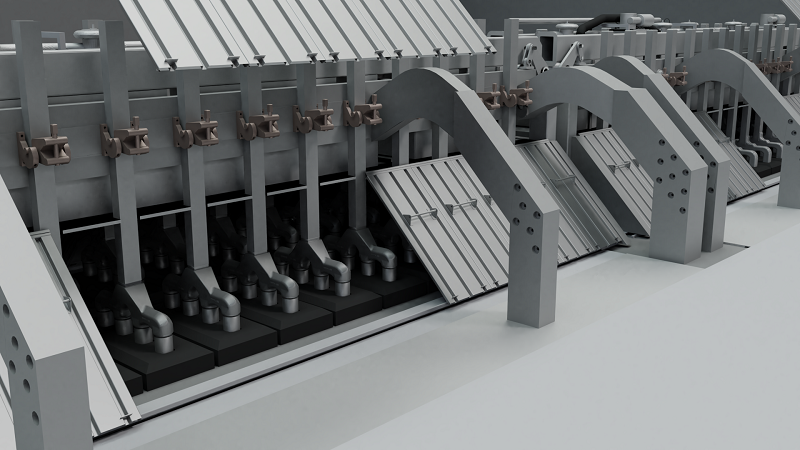

Thanks to 60 years of experiences combined with process knowledge Storvik offers equipment, machinery and maintenance activities in aluminium electrolysis.

Storvik has delivered equipment such as Anode Yoke, Tapping Pipe, Crucible and Lid in proprietary alloys, Crucible cleaning machine, equipment for cleaning of tapping pipe, maintenance of point feeders. All equipment is customized and adapted for each customers optimal operation in the electrolysis.

Recent deliveries are multifunctional remote controlled machine for cleaning of tapping pipes to Hydro Aluminium Karmøy, Improvement project for metal tapping lid to Hydro Aluminium Sunndal, Automatic cover handling for Hydro Aluminium Sunndal.