The story of Storvik is about entrepreneurship, creativity, and sustainability over more than 110 years. Storvik has been a significant part of the development of Sunndal as an industrial location, and it has been argued that the development in Sunndal in many ways illustrates the modernization of Norwegian society through the 20th century. Over the years, Storvik has expanded in various areas, from local acquisitions to international sales agreements and commitments that have helped strengthen the company.

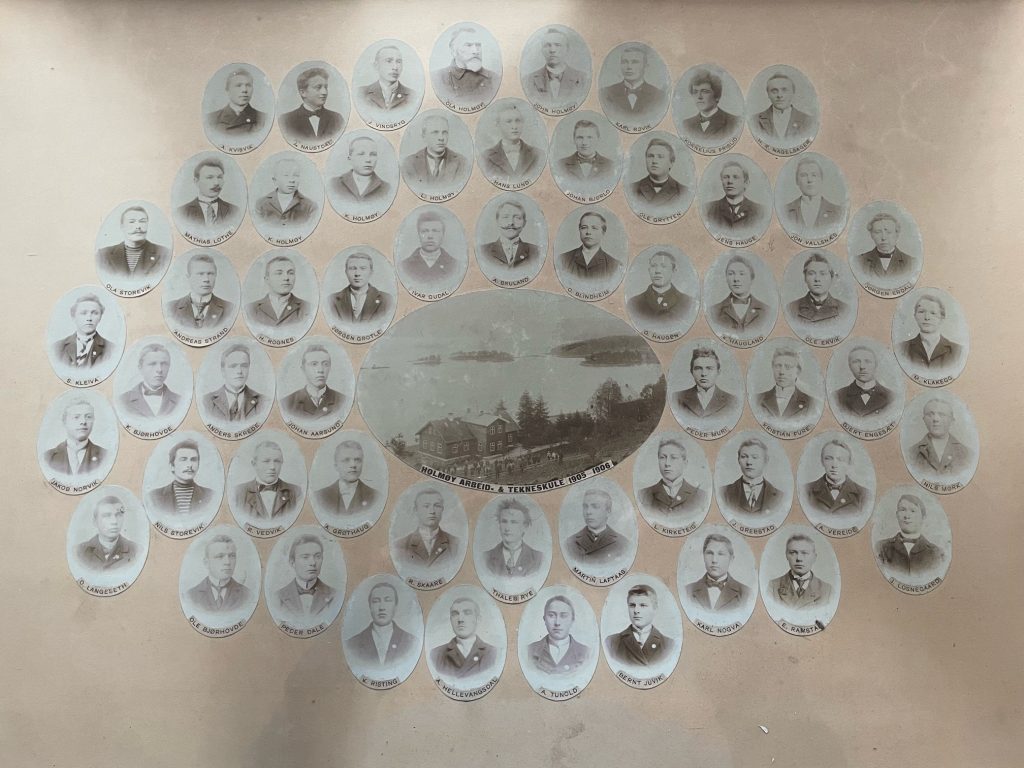

It all started with Nils Storvik. His father was a blacksmith, so it was natural for him to attend Holmøy Trade School in Hornindal in Sogn og Fjordane to learn to become a blacksmith. He quickly proved to be very skilled, and upon completing his education, he was offered a job as a teacher.

Initially, he was supposed to take over both the farm and the forge in Storvikan, but in 1909, he married Brit Sande and became a farmer at Sande in Sunndal.

Here, in 1913, he built a forge that he operated in addition to running the farm. Mainly, agricultural tools were produced in this forge, but Nils had a knack for finer blacksmithing and was therefore also entrusted with the task of making locks for Sunndal Sparebank. As the car fleet grew throughout the 20th century, there was a need for a blacksmith to fix car springs and more. Nils quickly excelled as one of the best in this field and built a reputation as the best in the district. Eventually, the reputation spread, and he became known across central Norway as a car spring expert.

Eventually, his son, Endre Sande, took over the forge. The assignments in the forge increased, creating a need for more hands and a more organized operation. Therefore, in 1952, Storvik Smieverksted was established. The operation was then moved to new premises in Øyagata.

As asphalt made its entrance in the late 1960s, the need for car spring straightening became less. However, other types of assignments continually grew in scope, especially related to construction activities and other business activities. Particularly important was a collaboration with Årdal and Sunndal Verk (ÅSV), which started in March 1976. Storvik Smieverksted was commissioned to repair a furnace, and from there, more and larger assignments followed. This led to more employees, and Storvik Smieverksted was converted into a limited company in 1978.

In 1978, Endre turned 64 years old and began to make plans for how the company should be carried forward. Here, the nephews, Nils Egil Sande and Nils L. Sande, come into the picture. Along with Halvard Halvorsen, these three became shareholders along with Endre. These three eventually took over the operation, and there was an ever-increasing need for more professionals after Storvik Smieverksted secured another major agreement with ÅSV. The solution was the takeover of, among other things, an industrial plant at Raudsand. This led the company to shift from blacksmithing to more mechanically oriented operations; it was therefore natural to change the name to Storvik Stål AS.

Storvik Stål AS started a close collaboration with Akvaforsk, and in 1985, Aquaprodukter AS was established. Together, they developed technical equipment for the rapidly growing aquaculture industry. This became an unqualified success and provided Storvik with a footing outside the aluminum industry. Later, Aqvaprodukter was merged into Storvik.

Around the same time, Storvik started cooperation with various Czechoslovakian companies. Storvik’s international expansion was catalyzed by this collaboration, a strategy that proved fruitful after the fall of the Iron Curtain. The establishment of a subsidiary in the Czech Republic in 1995 was the starting signal for high-quality, cost-effective production, opening doors to international markets.

In the mid-1990s, Storvik Stål merged with the companies Altek and AWS (Aura Watt), positioning the three companies stronger in the competition for new assignments, both nationally and internationally. The three companies now operated under the name Storvik AS, with a broader professional base, and the firm now had specialized departments in mechanics, electronics, project, and engineering.

When Hydro Aluminium (formerly ÅSV) decided to expand, Storvik was quick to compete for the contract. Hydro Aluminium was skeptical whether a local company had the capacity and resources to take on such a large assignment. Thanks to the merger and the network in the Czech Republic, Storvik was not only able to secure larger contracts, but all were completed without issues. Storvik had thus taken a quantum leap and was now ready to do business with the rest of the aluminum industry “worldwide.”

The internationalization process took Storvik to Russia, and with several successful contracts under its belt, Storvik subsequently established subsidiaries in Russia. Later, a subsidiary was also established in Iceland, and they got a major contract in Qatar. From there, the internationalization process went quickly. In 2008, the company turned over 138 million NOK, where nearly 70% of this turnover came from Sunndal works, and international deliveries accounted for 5%. Just 4 years later, in 2012, less than 25% of the turnover came from Hydro Aluminium Sunndal works, while almost 50% of the turnover came from deliveries abroad. In 2015, the turnover was up to 190 million NOK.

In 2016, Storvik acquired Heggset Engineering and established a branch office in Kristiansund. This significantly strengthened the company’s engineering team and opportunities to take on larger and more complex projects at home and abroad. Despite challenges such as the global pandemic and the conflict in Ukraine, Storvik has continued to grow. In 2020, Storvik Mosjøen AS was established, and the company strengthened its position in the Czech Republic by investing in the foundry RKL Slevarna s.r.o. In 2022, Storvik LLC in the USA was established, and the export share grows.

Today, Storvik represents a diversified business with four core areas: cast products, mechanical department, machine building & fabrication, and project &engineering. This range has made the company robust in the face of market changes, reflected in a turnover of over 460 million NOK in 2023.

Storvik’s story from a modest forge to a recognized international corporation underscores the company’s ability to innovate, adapt, and achieve sustainable growth over more than a century.