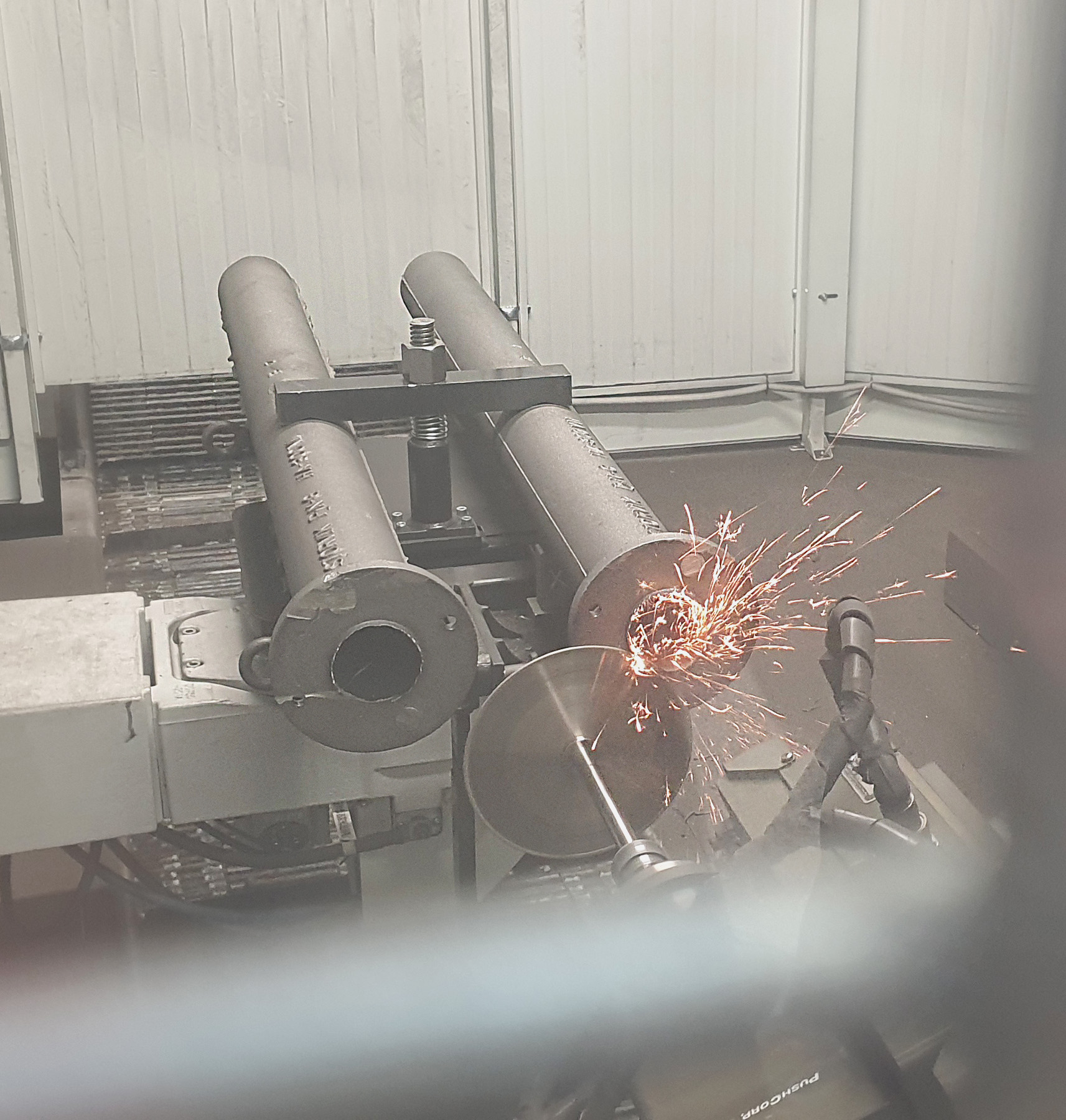

The world’s first foundry to introduce robotic grinding of metal tapping pipes

During the production of castings, grinding of the products can easily become a bottleneck as this is labor intensive and requires a large degree of manual grinding and handling. Our foundry in the Czech Republic, has been working for a long time to improve this and we can now proudly launch the solution – robotic grinding machines. Not only does this eliminate the bottleneck, but this is an extremely important measure for improved HSE. The solution means that the operator no longer has to grind manually and will then not be exposed to risk of cut injuries, dust, noise and strain on joints.

Our foundry in the Czech Republic invests significant amounts to automate and develop better methods to streamline production. When producing pipes and other castings, we have a strong focus on details and functionality that increases the service life of castings from Storvik. The new production solution will be an important step towards producing completely homogeneous pipes. As a co-owner, Storvik is very proud of our foundry and that we thereby further develop our position as Europe’s most advanced foundry.