Storvik has signed a new contract with a Norwegian aluminium smelter for the supply and installation of new thimble presses.

The aluminium smelter delivers high-quality, high-margin products to the automotive and can-end markets in Europe.

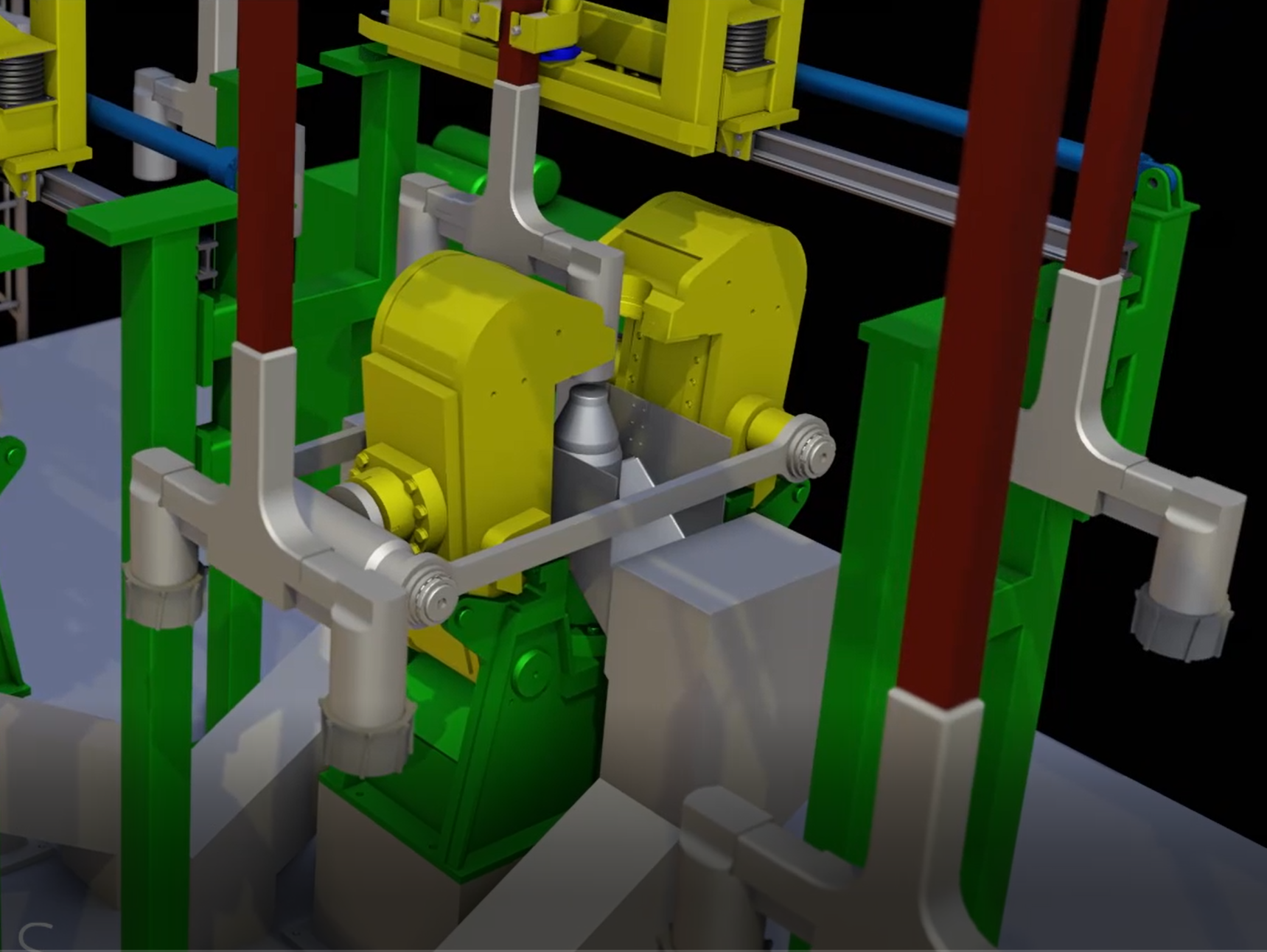

The consumed anodes from the potline are returned on daily basis and processed for re-use at the anode rodding shop. After the stripping of butts and bath, the stem bracket assembly passes through the thimble press, where the cast iron thimbles are stripped.

The project and its modern designs will be an upgrade into operations and maintainability of the production capacity of the rodding shop. In addition, will the thimble press station be compatible with the upcoming new anode configuration.

The scope of supply is as follows:

- New Thimble press in parallel with the existing press.

- New Thimble press to replace the existing press.

- Power and Free conveyor system modifications.

- Auxiliary equipment modification.

The two new thimble presses will be supplied by our partner SMV AS (Sunnhordaland Mekaniske Verksted AS). SMV is a multi-disciplined company working within the field of industrial mechanics and supplies a wide range of products for the metal process industry.

We are proud to be awarded the contract, and together with our partners, we look forward to the continued contribution of improvements to aluminium smelters worldwide. Anita Walør Heggem,Head of Project & Engineering