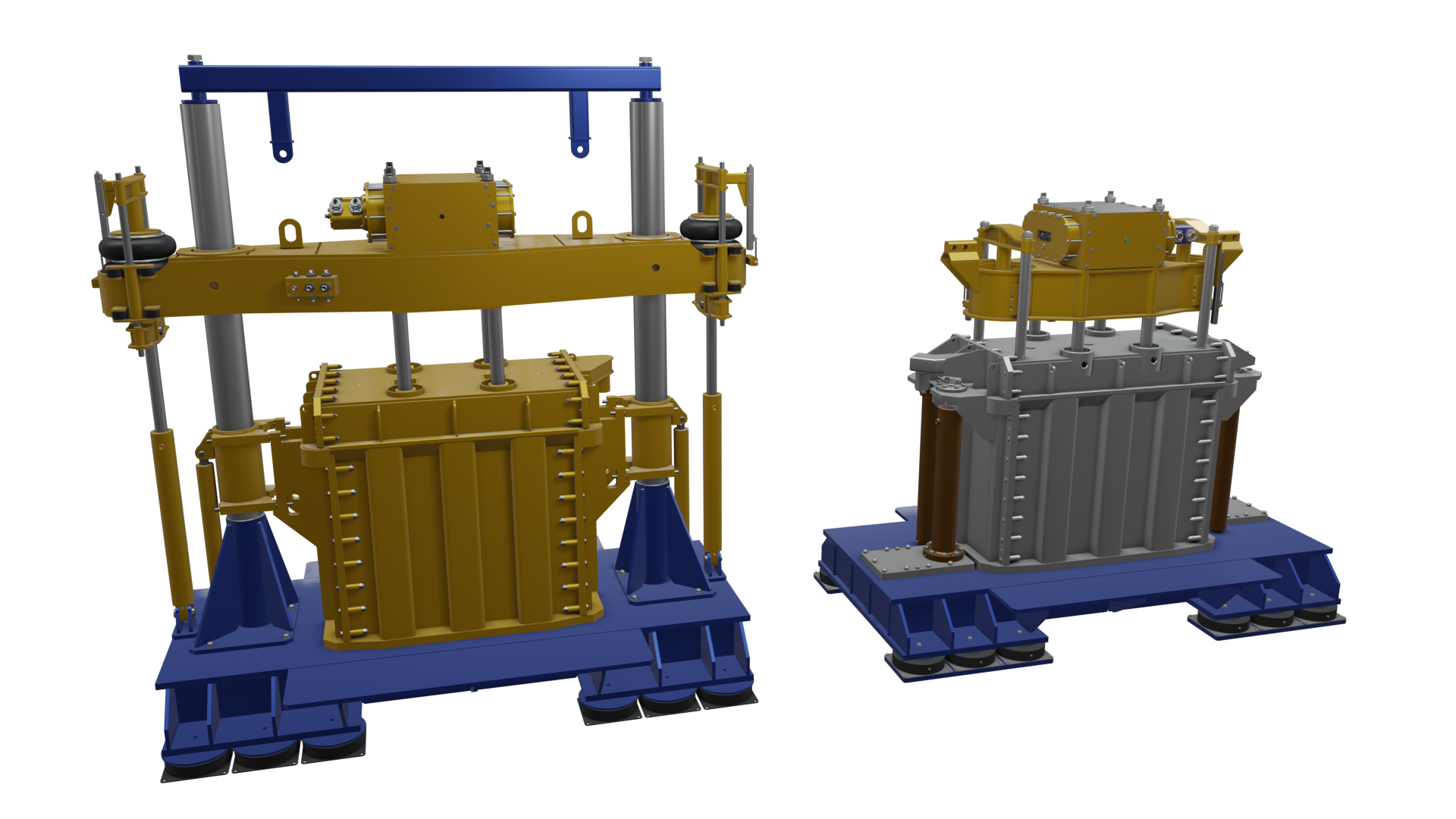

Storvik has entered a new contract with Hydro Aluminium Sunndalsøra (HASU) and Technology and Operational Support (TOS) for development of new technology for baked anodes.

This contract is possible by the help of Innovation Norway which funds parts of the contract.

Storvik has together with Hydro previously developed a machine which makes top quality anodes. This machine has been installed at Hydro and other plants in the world in today’s design for decades. Hydro continuously strive to produce the greenest aluminium possible, and to do so all stages of production need ongoing optimisation.

Storvik has over many years cooperated with Hydro and a strong team of engineers to develop this system.

With the help from Hydro and Innovation Norway we will test out new design for optimal production of baked anodes for Hydro. This is crucial to be able to enter new markets such as China.

“Hydro Sunndal greatly appreciates the opportunity to participate in the development of the next generation Vibrocompactor in collaboration with Storvik and Innovation Norway. The project is a good example of how collaboration and competence, developed over the years, leads to innovation that maintains competitive advantages in terms of productivity and quality. The goal is for the project to ensure the production of even better anodes, at lower costs through the development of more robust technology and sensory monitoring of the production process. ” says Roar Ørsund, Plant Manager at Hydro Sunndalsøra.